Our global client base spans a range of markets and MEMS device types, with a focus on high-value specialty applications.

Customer Success Stories

EMERGE

Read More . . .

AMFitzgerald executed:

- Foundry selection

- Mask tapeout

- Tech transfer

- Wafer test and measurement

LAWRENCE LIVERMORE NATIONAL LABORATORY

Read More . . .

AMFitzgerald has been working with LLNL to develop a novel three-axis micro-mirror with

- Working with LLNL scientists to adapt their designs for MEMS processing.

- Design, layout, and fabrication of several generations of mirror prototypes. AMFitzgerald engineers are performing all prototype fabrication at UCB Marvell Nanolab

- Perform metrology and process de-bugging

- In a more advanced prototype, integrated a third-party polysilicon through silicon vias (TSV) to improve mirror fill factor

PolyOptic Technologies, Inc.

Read More . . .

We designed two custom in-plane electrostatic switches, one having linear drive and the other rotary drive, for a micro fiber optical switching application. Our responsibilities included:

- ANSYS Multiphysics modeling and analytical modeling to size motor force, deflection, and operating voltage

- Interface with foundry engineers on process and design rules, tool capabilities, short loops

- Process integration and runsheet development

- Photomask layout and tapeout to 150 mm foundry

- Managed foundry engineers on behalf of client, reviewed in process data and provided foundry engineers with technical advice on wafers in progress

- Performed wafer-level electrical test on finished foundry wafers to confirm functionality. Used initial test data to further tune ANSYS models.

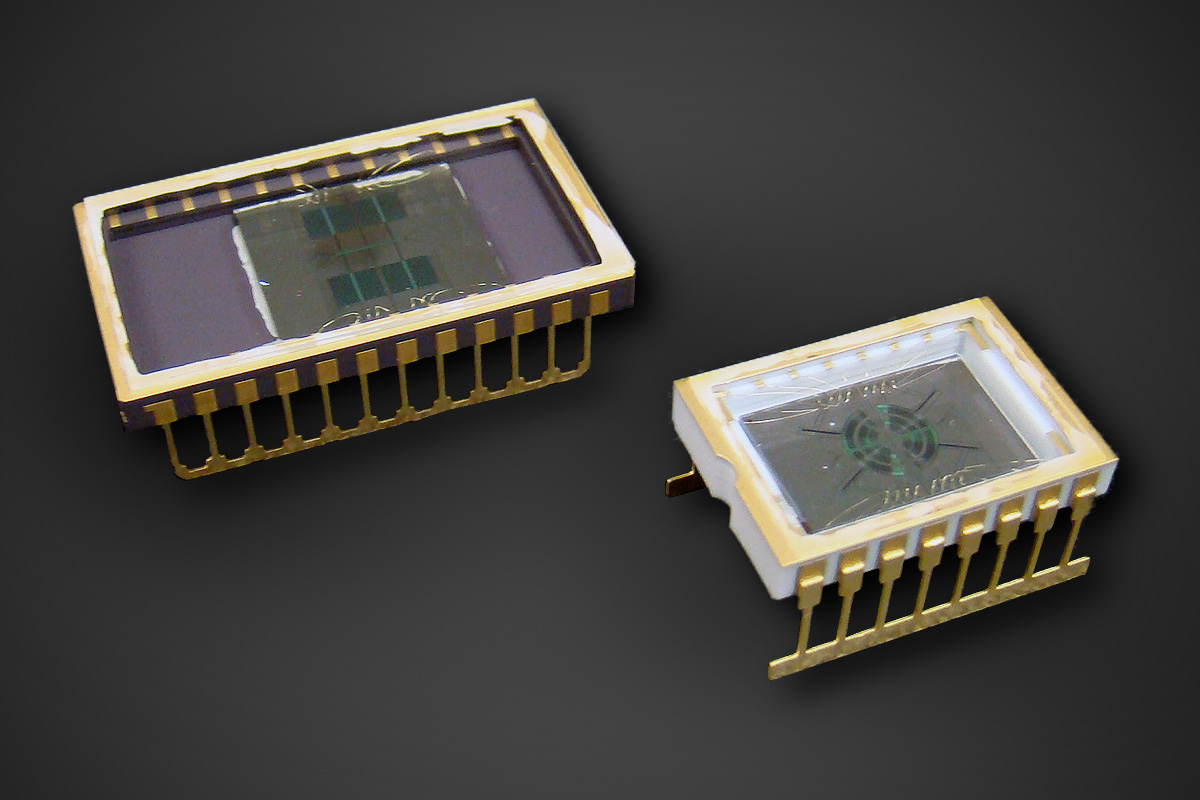

- Packaged switches in commercially-available open cavity packages and performed benchtop functional testing of switches

SOFANT TECHNOLOGIES, LTD

Read More . . .

- AMFitzgerald performed electrostatic simulations using ANSYS

- Developed a full process flow and fabricated prototypes

- AMFitzgerald later assisted with 200 mm foundry transfer and process improvements

INTERNATIONAL MEDICAL DEVICE COMPANY

Read More . . .

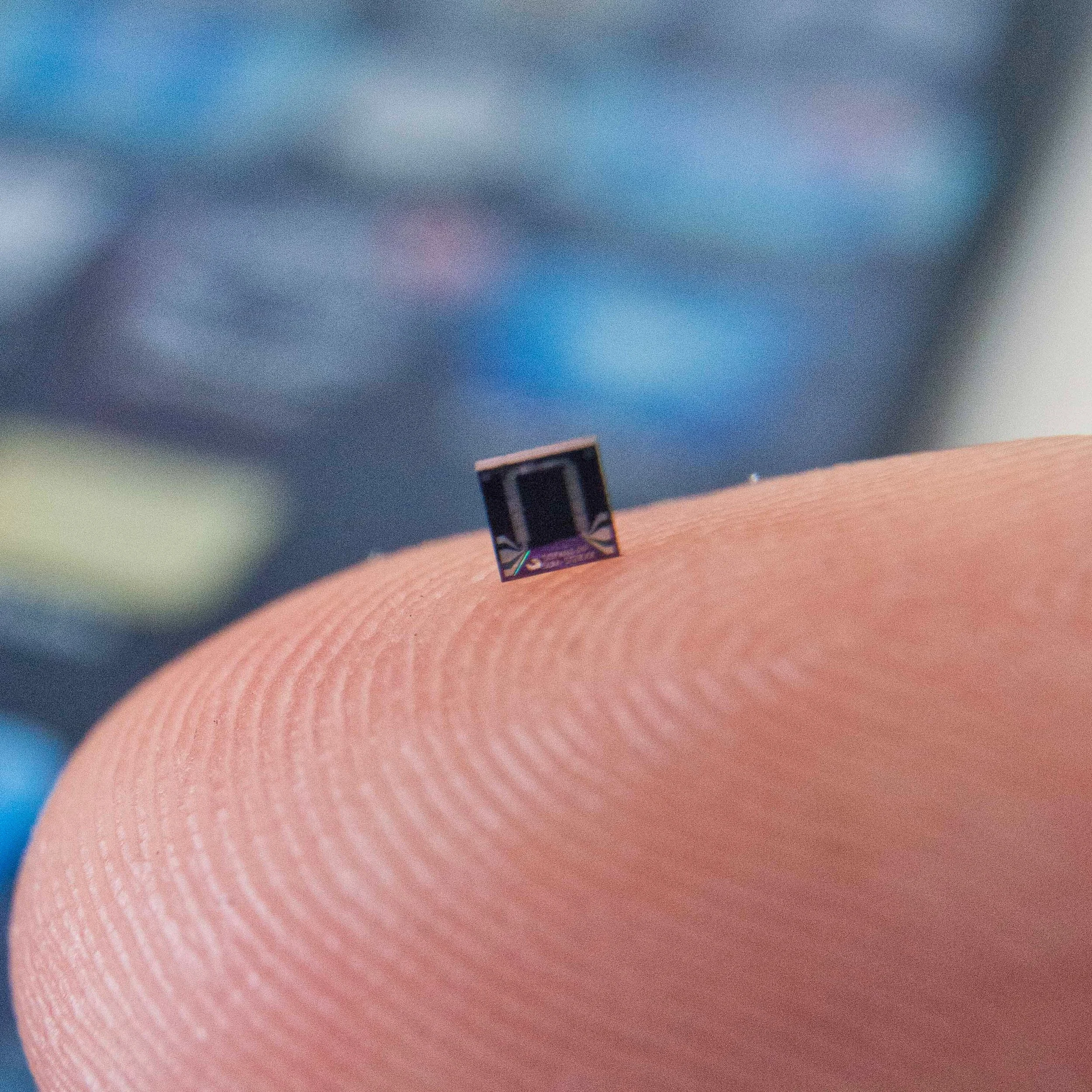

- The client was seeking a MEMS single-axis accelerometer for a cardiac pacemaker application. Due to the application, the client needed an unusual chip geometry.

- AMFitzgerald first conducted a broad survey to see if any commercially-available MEMS sensors might be used. We also presented pros, cons, budget and timeline for AMFitzgerald design a custom sensor.

- Because none of the commercial options were quite right, the client elected to have AMFitzgerald develop a custom accelerometer. The client favored using a standard foundry process platform for motion sensors, in order to provide a pathway to scalable 200 mm wafer manufacturing.

- AMFitzgerald designed the custom MEMS accelerometer using the motion sensor process design kit (PDK) and verified our design using simulation prior to tape-out. Functioning MEMS accelerometers with integrated microelectronic components were produced within the first prototype run at a 200 mm foundry. We collaborated with the customer to characterize the accelerometer’s performance while integrated with the product’s prototype electronics.

Public Semiconductor Foundry

-

Client was seeking to expand its core CMOS semiconductor foundry business to also address the MEMS market.

We analyzed and strategized on which MEMS products the foundry’s capabilities could best address with minimum capital investment. We provided an assessment of the MEMS process capabilities needed to fabricate such products and conducted a gap analysis of the foundry’s existing equipment set. We delivered a plan for equipment acquisitions needed to upgrade the foundry’s tool set to accommodate MEMS production.

The foundry executed our plan and gained several new MEMS customers.

Partial Client List

AMFitzgerald has been a key development partner to over 200 clients around the world since 2003. Our clients trust us with their most critical projects and return to us year after year. They include:

Mirion

MIT

Nevada Nanotech Systems

NovaSpectra

Panasonic ACOM-TC

Ricoh Innovations

Rigetti Computing

SemQuest

Silicon Light Machines

Silicon Microstructures

Sofant Technologies, Ltd

Sorin Group

Stanford University

SunPower

Symmetricom

Tactus Technology

UCSF, Ophthalmology

University of Nevada, Reno

Wave 80 Biosciences

Weill Medical College of Cornell University

Yole Développment

Aclima

Agilent Technologies

Advanced Diamond Technologies

Alfred E. Mann Foundation

Applied Materials

Ascendance Biotechnology

Bay Materials

Caliper LifeSciences

Cypress Semiconductor

DARPA

Edge Embossing

Emerge

Endotronix

Finisar

Fluxion Biosciences

Hoowaki

Lawrence Livermore Nat'l Labs

Maxim

Measurement Specialties

Micralyne

Micrel

Microfabrica

Member Since 2006.

“AMFitzgerald provides top-notch MEMS consulting expertise. Whether analysis, design, fabrication, or hands-on test and characterization, they have always delivered value in helping us achieve our goals.”